Butterfly valves are among the most utilised available today because they’re low-cost, quick to operate and easy to install. The butterfly valve is a quarter-turn rotational motion valve, similar to a ball valve. It operates by rotating a circular disc through an external handle to stop, regulate and start fluid flow. In this article, we explain a butterfly valve and its main components and answer, “How do butterfly valves work?”.

What is a butterfly valve?

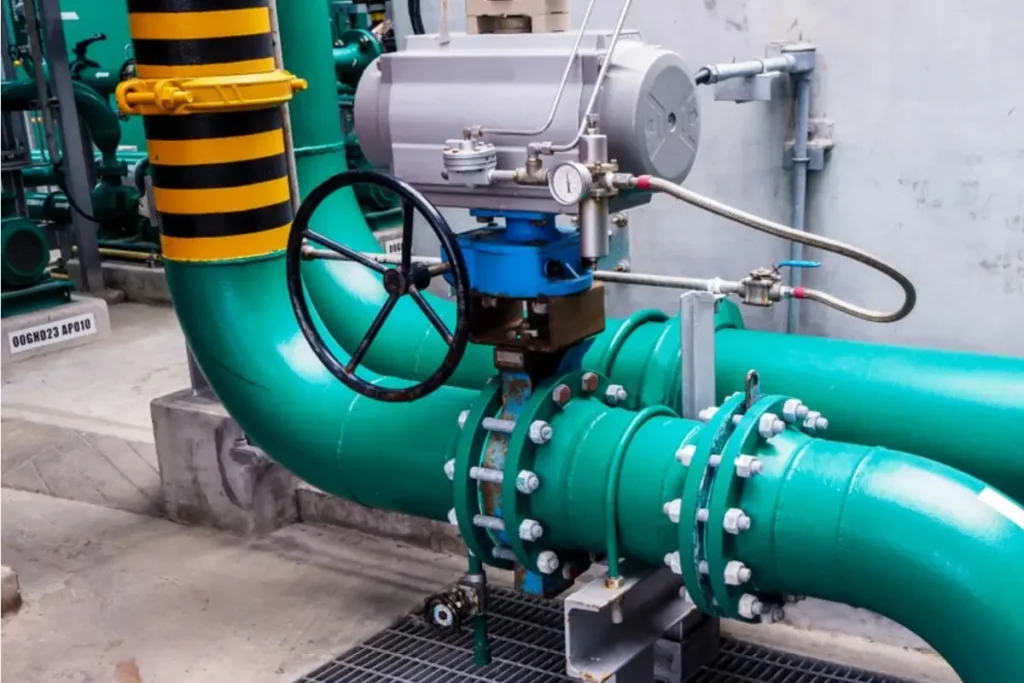

Butterfly valves have a short circular-shaped body available in either Wafer, Lug or Double Flange configurations. A thin circular disc sits inside the body and is connected to a stem that projects through the body. This allows the disc to be rotated through an external handle or operating mechanism. The disc sits flush in the valve seat, perpendicular to the flow, when the valve is closed, stopping the fluid flow. When the disc is rotated by turning the external handle, it opens, allowing flow to pass through the valve. The butterfly valve design allows the disc to be positioned between the fully open and closed positions to control the fluid flow to the desired volume and velocity.

The short body design of the butterfly valve provides the benefits of fitting into tight spaces, being lightweight and subsequently cost-effective. It’s popular because of its isolation capabilities and the ability to be opened and closed quickly. Butterfly valves suit applications that handle high flow rates at relatively low pressures and fluids with small particles.

How do butterfly valves work?

Before we can answer “How do butterfly valves work?” we need to identify the main components of their construction.

Butterfly valve components

Here are the main components used in all butterfly valves:

- The body connects the pipe’s two sections and protects the valve’s internal parts.

- The seat is located on the inside diameter periphery of the body and seals the disc. The most common type of butterfly is the ‘concentric’ type, where the seat is manufactured from an elastomeric material that fully envelopes the body’s internal surfaces.

- The disc is a thin, circular piece of metal in the middle of the valve.

- The stem connects the disc to an exterior handle and is responsible for turning the disc.

Working Principle

So now we know the main components that make up the valve, but how do butterfly valves work? The disc is responsible for the main functionality. The disc sits flush in the seat to isolate fluids in the pipe. When opened, the disc turns away from the seat and towards the centerline of the adjacent piping so that fluid can flow through. The disc is connected to an external handle by the stem. When an operator turns the handle, they operate the valve by turning the stem and, therefore, the disc.

Valve operation can be performed manually, pneumatically or electrically, depending on the size and type of butterfly valve and the specific application requirements.

Smaller size manually operated valves incorporate a notched locking plate. This means the handle can be suitably positioned between the fully open and closed positions to control the required flow rate through the valve. The stem and disc are rotated through a worm-type gearbox and handwheel for larger manually operated valves. The gearbox is sized and selected to ensure that the operator only requires reasonable effort to open and close the valve regardless of the valve’s size and operating pressure.

When fitted with a pneumatic actuator, electronic switch mechanisms provide the air pressure to open and close the valve. Pneumatic actuators can be double-acting, where air is used to open and close the valve. They are also available with an internal spring that will automatically open or close the valve should a loss of air pressure to the pneumatic actuator occur.

The fitting of an actuator automates the valve operation so that it can be opened and closed from a remote control room.

Final thoughts

Butterfly valves are robust, cost-effective and easy-to-use valves for isolating and controlling fluid flow. They can include pneumatic and electrical actuators to assist in opening and closing the valve for more demanding applications. The extensive range of applications for which butterfly valves are suited makes them a common choice for many industrial applications. Ready to find a suitable butterfly valve for your system? John Valves can help.