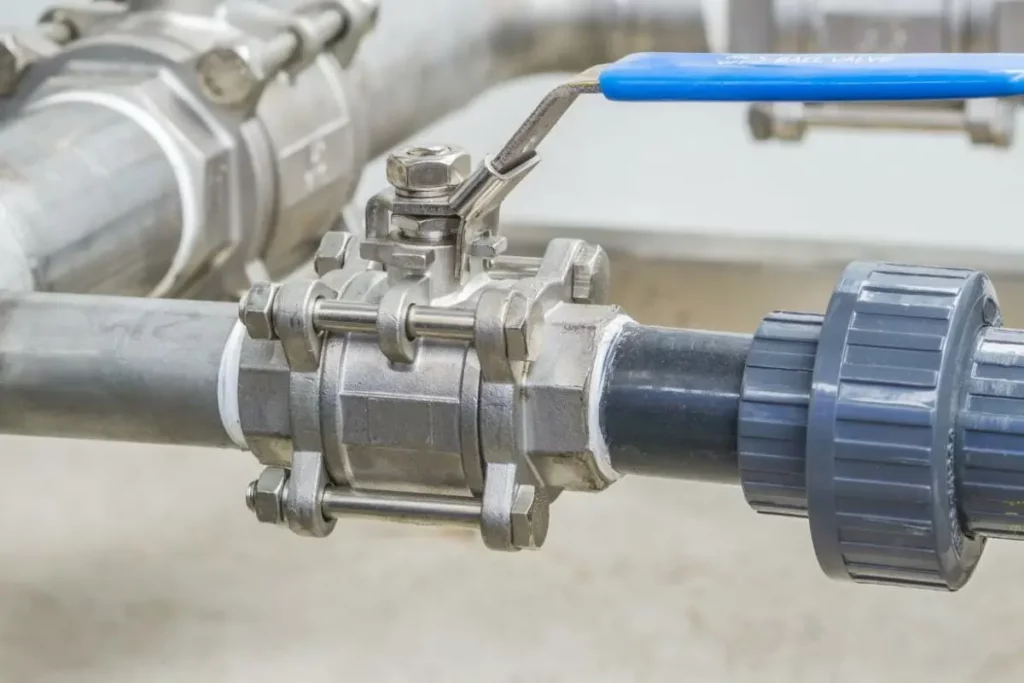

A ball valve is a shut-off valve that controls the flow of a liquid or gas using a rotary hollow spherical ball. Ball valves are popular because of their durability, strength, and affordability. They are easy to install, with a quarter-turn operation that makes them efficient to use. Ball valves have a basic design that makes them a reliable flow control component. They offer steady isolation in low-cycling applications. Ball valves appear in various industrial processes such as exploration, transmission, and refining.

The durability and utility of the design mean that you’ll find ball valves adapted to many specific applications. You can set up ball valves for manual operation or mount them with pneumatic, electronic, or hydraulic actuation for remote control applications.

Ball valves are subject to failure like any component of a dynamic system. It’s important to spot signs early before the damage makes repair impractical.

Reasons You Need Ball Valve Repair or Replacement

Ball Valve Jamming

In most industrial processes, jamming occurs when foreign matter enters the system causing the cavities around the ball and seats to be ‘clogged’. Jamming also occurs when slurry or solids passing through the lines are part of normal process operations. In either case, if a ball valve becomes jammed, it will cause long-term damage or deformation. The jamming of a ball valve can cause scratches and dents to the ball or tear the valve’s seals.

A Ball Valve That Fails to Cycle

If a valve does not cycle or operate, it could be due to a jam of the ball involving a foreign object or clogging. A cycle failure may also be caused by the valve’s stem assembly, actuator, or manual lever problems. If cycle failure occurs in a new system or after a significant redesign, the actuator could lack the necessary power to cycle the valve. Whenever a valve fails to cycle, it can signify a problem in the actuation system.

A Closed Ball Valve That Leaks

Ball valves are designed to offer complete isolation. When a valve works for the application, it should do precisely that. If a ball valve in the closed position allows leakage to flow through, this is a bad sign. Deformed or damaged seals are a common cause of leaking. Damage to the ball itself can cause leaking. In either case, immediate corrective action will keep ball valve repair costs low and prevent significant problems.

A Ball Valve That Leaks at the Stem

The other important area on a typical ball valve where leaking can occur is around the stem assembly. Worn-out packing seals due to wear and deformation in older valves is the main reason that leakage at the stem will occur. Errors during the installation of the stem seals during a rebuild can also be a cause of this issue.

An Increase or Change in the Level of Noise or Vibration

When you work in an industrial setting, you know your system in ways that a layman does not understand. You learn to hear how it should sound and act. It makes you the best person to notice changes that can be clues about how the system functions. When you see an increase or change in the noise or vibration near a valve, that’s a sign that it requires immediate repair.

- Fig 801 Single Piece Ball Valve

- Fig 802 Two Piece Ball Valve

- Fig 803 Three Piece Ball Valve

- Fig 804 Flanged Piece Ball Valve

Conclusion

The decision on whether to repair or replace a ball valve is dependent on many factors. These include the degree of damage to the valve’s internal components as well as the size and type of ball valve. In a lot of instances, particularly where the valve is only small in size, it would be more economical to simply replace the valve. If you require professional help for your ball valve repair or replacement, don’t hesitate to contact us. We carry replacement parts for a huge number of ball valve models!

Read More: