Y-type valves are, not surprisingly, characterised by the Y-shaped design, which integrates the valve body and the branch into a single assembly. This configuration offers many benefits, including reduced pressure drop across the valve, ease of maintenance, and compactness, which can be particularly advantageous in tight spaces or where a straightforward flow path is essential.

Y-type valves are adaptable and are used in various applications, including fluid control in piping systems and filtration processes. They can also be found in complex infrastructure in industries such as chemical processing, power generation, water treatment, and oil and gas. The unique design allows for efficient flow management. The branch is typically used as an outlet or a service connection that can be accessed without disrupting the main flow.

Y-type valves are available in various materials, such as stainless steel and brass, each suitable for different media (liquids or gases) and operating conditions (temperature and pressure levels). They can also feature different operation mechanisms, such as manual handwheels, pneumatic actuators, or electric motors, making them adaptable to simple and sophisticated control systems.

The specific choice of a Y-type valve depends on factors such as the nature of the fluid (corrosive, abrasive, etc.), pressure and temperature requirements, and the specific application’s needs. Their design facilitates flow and simplifies the installation and maintenance processes, contributing to their popularity in many industrial and commercial applications.

Y-Type Plug Valves

Y-shaped plug valves are designed with a Y-shaped configuration that offers distinct advantages in fluid control applications. The design integrates the pathway for the fluid and the plug mechanism to optimise flow efficiency and reduce turbulence.

Design and Operation

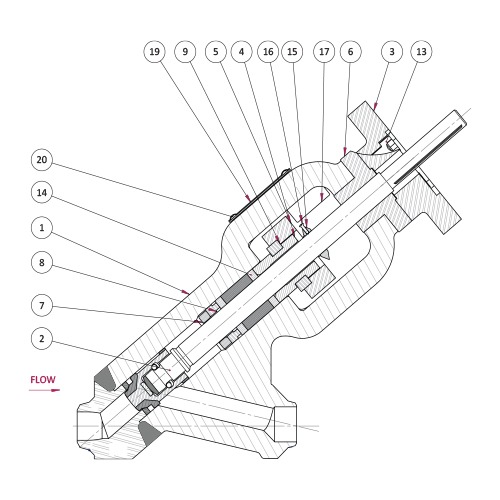

The valve consists of a body with a Y-shaped passageway and a plug that fits snugly within the body. The plug, the component that opens or closes the valve, can be rotated by 90 degrees to align with the flow path for opening or perpendicular to it for closing.

The plug may have one or more passages to allow fluid to pass through when the valve is open. The design of these passages can vary depending on the application’s specific requirements, including the need for full or partial flow control.

Y-Type Advantages

- Efficient Flow Control

The Y shape facilitates a more natural flow of fluid with less resistance, which can be particularly beneficial in applications requiring the efficient transport of fluids. - Versatility

These valves can handle various media, including liquids, gases, and slurries. They are well-suited for both throttling and on/off service. - Reduced Wear

The smooth transition path for fluid reduces turbulence, which can lower the wear on the valve components, extending the valve’s lifespan. - Compact Design

The Y configuration allows for a more compact design than other valve types, which can be advantageous in systems with limited space.

Applications

Y-shaped plug valves are used in industries where efficient flow control and space savings are essential. They are commonly found in chemical and petrochemical plants, water treatment facilities, and other industrial environments where controlling the flow of fluids is crucial.

Materials and Types

These valves can be made from various materials, including stainless steel, stellite, alloy steel, and others capable of withstanding the operating environment’s demands. They may also feature different seals and packing materials to ensure tight shutoff and accommodate various temperature and pressure conditions.

Y-shaped plug valves are a practical choice for applications requiring efficient flow control, durability, and compactness. Their design and operational features make them a versatile solution across a broad spectrum of industrial applications.

Ordering a Y-Type Valves

Y-type valves are often used in specific environments. Our engineering team can discuss your technical requirements and design a solution. Our expert team with manufacture, assemble and test your new valve.