There are many different applications for butterfly valves, some of which may be closer to home than you think!

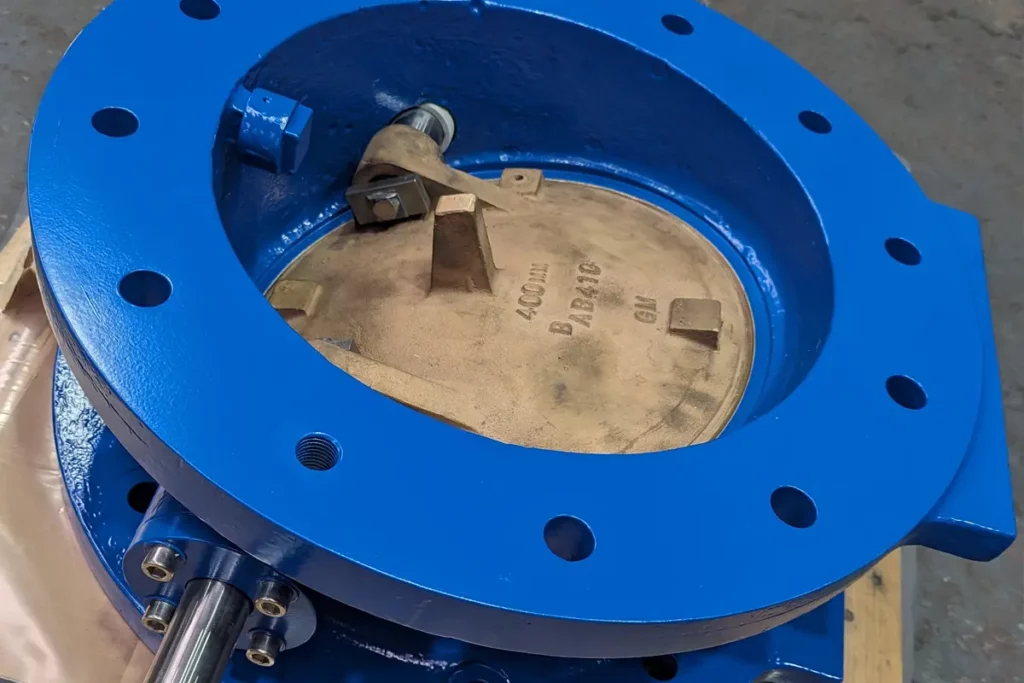

Butterfly valves are incredibly lightweight and easy to use. Professionals may prefer using butterfly valves over other types of valves for applications that require measurement control and abrasion resistance. Modern rubber compounds and polymers that can coat more sensitive parts of the valve make them operate even more reliably. Generally, they work well with large diameter lines where their physical size makes them an economical and practical choice.

Due to their ability to handle high volume flows, butterfly valves aren’t always the best option for ‘fine-tuning’ flow control applications. Butterfly valves sized by a professional ensure the correct flow and fit at the best possible price.

Typical Applications of Butterfly Valves

Typical Applications

Butterfly valves are ideal for use in tight and awkward spaces. This is because they are the narrowest valves available in the market. Butterfly valves are commonly used on ships, in equipment ‘skid’ setups, and even in piping systems within buildings.

Butterfly valve applications include:

Throttling

Butterfly valves work well for throttling. Throttling is the process of controlling the flow of fluid through the valve by turning the handle to achieve a desired flow rate.

Lower Pressures and Temperatures

Butterfly valves are great for a range of temperatures and pressures but are notably used for lower pressures and ambient temperatures. Specific design butterfly valves can operate at temperatures as low as -195 degrees Celsius and to very high temperatures, which makes them extremely versatile when it comes to flow control at a range of temperatures.

Quick Open and Close

The handles on butterfly valves are proportional in size to the required rotational torque of the disc, and they open and close easily. Being a quarter turn operation valve, they’re quick to open and close while being suitable for a variety of applications. Butterfly valves were not originally designed for air-tight sealing, however, modern butterfly valves incorporate seats that allow for tight sealing while still ensuring quick opening and closing.

Lower Maintenance and Better Pricing

Butterfly valves are unique in that their construction uses materials that can withstand a wide range of temperatures while remaining relatively inexpensive. As one of the more reliable valve types, they do not require a great deal of maintenance, unless they are exposed to higher pressures or consistent slurry applications, which their design cannot handle too well.

There are certain applications in which butterfly valves would not be suitable, even though butterfly valves have a broad range of applications. They aren’t great with slurries since the valve disc is always present within the flow, even when fully open, erosion subsequently reduces the service life of the valve. They are versatile, but they are also delicate.

Butterfly Valves Are Suitable For:

Throttling of Large Fluid Flows

Throttling of flows in larger pipelines is universally believed to be best achieved with butterfly valves. To allow large amounts of fluid to pass through, the valve doesn’t even need to be fully open, and a quarter turn is enough to open or close it. Relatively linear flow characteristics make it easy to gauge and control the flow.

Constant Load Application

In addition to regulating large flows better than other valves, butterfly valves are also able to handle constant loads. The valve disc is relatively thin, and when it is completely open, offers minimal resistance to the flow. This is why this particular valve is preferred in large piping systems.

Butterfly valves however are relatively delicate, which makes them unsuitable for flow control where the need for high pressure loss is required.

Space-Restrictive Applications

Butterfly valves are commonly used in systems where there are installation space constraints as their bodies are narrow. The butterfly valve is one of the best valve types for fitting into tighter areas. The other best part is they’re very simple to size, and there are a lot of different butterfly valve types and sizes to choose from.

Summary

In order to determine which type of valve you need to use, you must consider all your options. If you choose a butterfly valve, it should be able to provide consistent flow even with only a quarter-turn of the valve.When searching for the best butterfly valve, you will always want to be able to work with professionals who can guide you, as well as offer you the most extensive range of sizes and brands. If you’re ready to discuss your project, contact the team at John Valves to talk through your needs and discover your options.

Read More: