Safety Relief Valves (SRVs) and Pressure Relief Valves (PRVs) play crucial roles in dealing with overpressure scenarios that might result in catastrophic outcomes. For many in the industry, the question arises: which one is more suitable for your needs? In this article, we look into the characteristics of SRVs and PRVs, their operational mechanisms, areas of use, and various performance-related aspects.

Importance of Relief Valves in Pressure Management

Relief valves play a pivotal role in pressure management within industrial systems, offering several indispensable benefits:

- Safety Assurance

Relief valves are paramount for upholding safety standards. They avert the perilous consequences of excessive pressure buildup, which could otherwise result in equipment failures, leaks, or even catastrophic explosions. - Equipment Preservation

By promptly releasing surplus pressure, relief valves shield valuable equipment from potential damage due to overpressure, ensuring its longevity and reliability. - Uninterrupted Operations

Effective pressure management via relief valves is instrumental in sidestepping process disruptions, costly downtime, and the need for extensive repairs. This facilitates smooth and efficient operations, ensuring productivity remains uninterrupted.

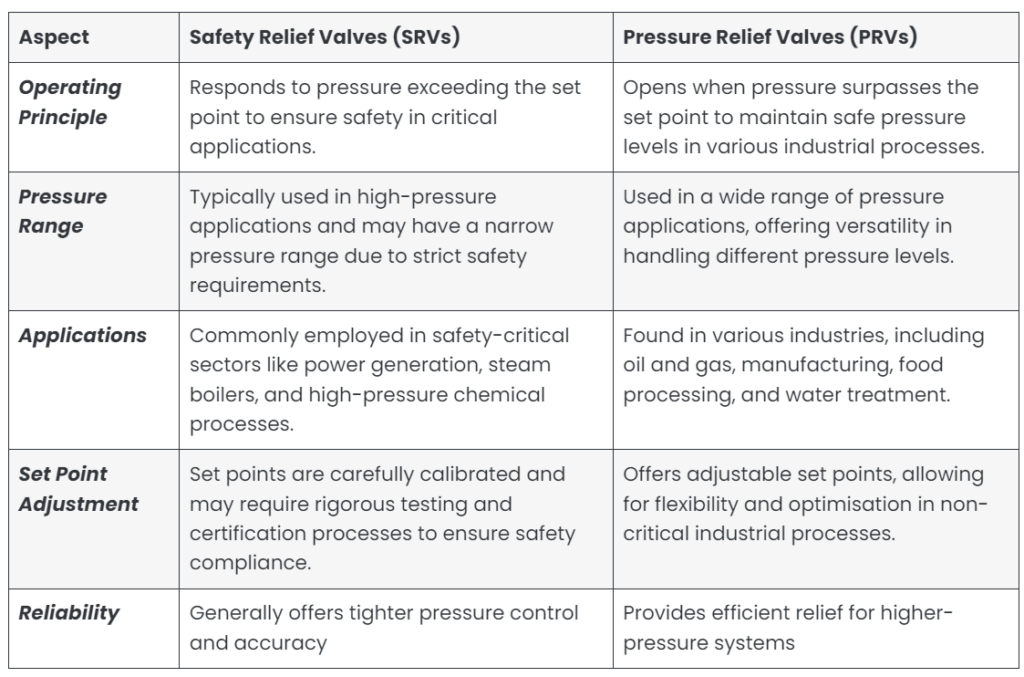

Understanding the Difference between SRV and PRV

Below is the table highlighting the key differences between Safety Relief Valves (SRVs) and Pressure Relief Valves (PRVs):

As such, SRVs are typically used in situations where the primary concern is safety, whereas PRVs are used for both safety and process control.

Safety Relief Valves: Features and Applications

Safety relief valves relieve excess pressure, preventing system failures. SRVs have adjustable set points, reliable operation, and high accuracy in pressure control.

Overview of Safety Relief Valves and Their Operation

SRVs operate through spring-loading or pilot control mechanisms that relieve the pressure when it exceeds the set point. SRVs include a valve disc, spring, and adjustable pressure set point. When the valve is opened, it allows fluid or gas to escape, reducing pressure.

Critical Applications and Industries that Benefit from Safety Relief Valves

Safety Relief Valves have wide-ranging applications:

- In oil and gas, they protect refineries, pipelines, storage tanks, and offshore platforms.

- Chemical processing plants use SRVs to safeguard reactors and distillation columns.

- Power generation facilities rely on SRVs for safe operation.

- Pharmaceutical, food, beverage, and water treatment industries also benefit from SRVs.

- They protect equipment, personnel, and the environment from excessive pressure risks.

Also read: Why Do I Need a Safety Relief Valve?

Pressure Relief Valves: Features and Applications

Pressure Relief Valves (PRVs) are integral components within pressure management systems, responsible for maintaining safe pressure levels and preventing overpressure situations. These valves are designed with specific features that enable them to perform reliably in a wide range of industrial settings.

Overview of Pressure Relief Valves and Their Functionality

Pressure Relief Valves are designed to automatically open and relieve excess pressure when it surpasses a predetermined threshold. Their primary function is to safeguard equipment and processes from the potential damage associated with high-pressure conditions.

Key Applications and Industries that Utilise Pressure Relief Valves

Pressure Relief Valves have a wide spectrum of applications, making them indispensable in numerous industries:

- PRVs are critical for maintaining pressure in aircraft systems.

- They ensure safety and quality in drug manufacturing processes.

- They protect equipment and product integrity during food and beverage production.

- Pressure relief valves are applied in ship systems to prevent overpressure.

- They are essential for maintaining the integrity of water purification and distribution systems.

- PRVs are used to maintain optimal pressure in heating, ventilation, and air conditioning systems.

Performance Comparison: Safety Relief vs. Pressure Relief Valves

Both valves have different performance characteristics and are used for different applications.

- SRVs are typically designed to protect equipment and personnel from overpressure situations. They generally are set to open at a lower pressure than PRVs and have a smaller blowdown. It allows them to respond more quickly to overpressure events and prevent equipment damage or personal injury.

- PRVs are more commonly used for system protection and process control. They are typically set to open at a higher pressure than SRVs and have a more considerable blowdown. It allows them to maintain a more stable pressure in the system.

Examining Relief Capacities and Set Pressures

Relief capacity refers to the amount of liquid or gas a valve can discharge per unit of time. It is essential to ensure that the relief capacity of a valve matches the requirements of the system it is protecting.

Set pressure determines the point at which a relief valve opens to relieve pressure. Before selecting a suitable relief valve, you must evaluate the working and design pressure for your systems.

Understanding Blowdown and Resealing Characteristics

Blowdown is defined as the variance between the established pressure and the pressure at which a relief valve resettles. Opting for a narrower blowdown leads to finer control over pressure, whereas a larger blowdown might cause fluctuations in pressure, potentially impacting the system’s effectiveness. The ability of a relief valve to reseal effectively is vital in averting leaks or excessive release following the pressure relief process.

Choosing the Right Valve for Your Needs

When choosing a relief valve, it is essential to consider the type best suited for the application.

Factors to Consider when Selecting Relief Valves

The following are some of the most important factors to consider when selecting relief valves:

- Relief capacity

The amount of liquid or gas a valve can discharge per unit of time. - Set pressure

The pressure at which the valve opens to release the pressure. - Blowdown

Difference between the set pressure and the pressure at which the valve re-seats. - Reseating Characteristics

The ability of the valve to close tightly after relieving the excess pressure. - Materials of Construction

The materials that the valve is made of must be compatible with the liquid or gas flowing through it.

Matching Valve Types to Specific Industry and Process Requirements

The choice of a relief valve varies based on the specific needs of the industry and its processes. For example, in the oil and gas industry, Safety Relief Valves (SRVs) are generally preferred. Here they safeguard equipment and personnel against overpressure incidents. Conversely, Pressure Relief Valves (PRVs) are frequently employed in the chemical industry to ensure consistent pressure within processing systems.

Seeking advice from seasoned experts is crucial when choosing a relief valve, to ensure the selection is ideally tailored to your unique application requirements.

Regulatory Considerations for Relief Valve Selection

The regulatory considerations for relief valve selection in Australia include the following:

- Type of liquid or gas that will be flowing through the valve

- Pressure and temperature at which the valve will be operating

- Amount of liquid or gas that needs to be relieved

- Safety requirements of the application

- Environmental conditions in which the valve will be used

Ensuring Valve Conformity with Applicable Codes and Standards

The following steps will help to establish that the valve confirms the applicable codes and standards in Australia:

- Purchasing the valve from a reputable supplier

- Request a copy of the valve’s test certificate

- Confirm that the valve is marked with the relevant codes and standards

- The valve should be inspected and tested by qualified technician

Maintenance and Testing

Safety relief valves (SRVs) and pressure relief valves (PRVs) are critical safety devices that must be adequately maintained and tested to establish reliability.

Importance of Regular Maintenance for Proper Valve Performance

Regular maintenance of SRVs and PRVs includes inspection, cleaning, and testing. This helps verify that the valves are in good working condition and can operate correctly.

Testing Procedures and Best Practices to Ensure Valve Reliability

The testing procedures and best practices for SRVs and PRVs vary depending on the type of valve and the application.

Here are some of the standard testing procedures for SRVs and PRVs:

- Bench testing: It involves testing the valve in a controlled environment.

- In-site testing: It consists of testing the valve in its operating environment.

- Hydrostatic testing: It consists of testing the valve with a liquid inside it under high-pressure conditions.

The best practices for testing SRVs and PRVs include:

- Have a qualified technician perform the testing.

- Following the manufacturer’s instructions.

- Documenting the test results.

Following these best practices ensures that your SRVs and PRVs are adequately tested and maintained.

Cost Considerations

The cost of safety relief valves (SRVs) and pressure relief valves (PRVs) in Australia varies depending on the size, type, and construction materials. However, in general, SRVs are more expensive than PRVs.

Evaluating Initial Investment and Total Cost of Ownership

When evaluating the cost of SRVs and PRVs, it is essential to consider the initial investment and the total cost of ownership. The total cost of ownership includes the initial investment, maintenance costs, and replacement costs.

Balancing Performance and Budgetary Constraints

When selecting SRVs or PRVs, balancing the performance requirements with the budgetary constraints is essential. Choosing a less expensive valve that does not meet all the performance requirements may become useless.

Similarly, investing in a more expensive valve that exceeds the requirement of your system is also not recommended.

Here are some of the factors to consider when balancing performance and budgetary constraints:

- The criticality of the application

- The potential consequences of a failure

- Proper evaluation of working conditions

- The maintenance and testing requirements

- Related: Quick and Easy Overview About Bronze Safety and Relief Valves

Safeguard You Systems with John Valves.

When choosing a relief valve, it is essential to consider the type best suited for the application. John Valves is a leading manufacturer of relief valves in Australia. We offer a wide range of valves to meet the needs of various industries. Our valves are designed to meet the highest standards of quality and safety.

Contact us today to learn more about our relief valves and how we can help you protect your industrial system from overpressure.