Beneath the surface of industrial operations, where fluid control plays a crucial role, lies a vital component that ensures precision, reliability, and safety: the globe valve. Among the various types of globe valves, one design stands out for its unique sealing mechanism and exceptional performance – the bellow sealed globe valve.

In this blog, we will explore the features, types, and applications of bellow sealed globe valves, highlighting their importance in diverse industries and understanding how they contribute to efficient fluid control systems. Let’s get started.

What are Bellow Sealed Globe Valves?

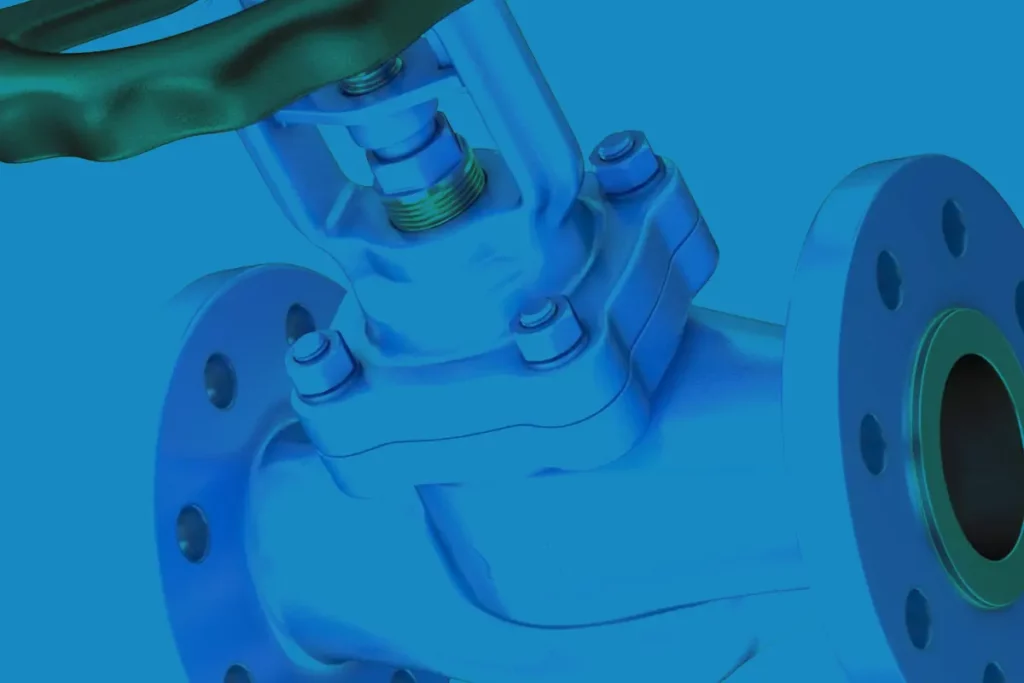

Bellow sealed globe valves are a specialised type of globe valve that incorporates a bellows element as part of their sealing mechanism to prevent the fluid from contacting the stem of the valve. This provides enhanced reliability, improved performance, and increased durability in demanding industrial environments. The bellows, typically made of metal or other high-strength materials, provide a flexible and hermetic seal that effectively prevents leakage and minimises fugitive emissions.

The design of bellow sealed globe valves features a globe-shaped body with a movable disc or plug that regulates the flow of fluids. The bellows is positioned around the valve stem and sealed to the disc and stationary bonnet of the valve, protecting the stem and isolating the process fluid from the external environment. This unique sealing arrangement offers several advantages, including enhanced resistance to high pressures, temperature variations, corrosive substances, and abrasive media.

Types of Bellow Sealed Globe Valves

Typically, there are two common types of bellows used in bellow sealed globe valves:

- Forged Bellows

Forged bellows are manufactured by shaping a single piece of metal through a forging process to create a convoluted or corrugated shape. This type of bellows offers excellent structural integrity, strength, and resistance to high pressures and temperatures. Forged bellows are commonly used in industrial applications where robustness and durability are paramount. - Welded Bellows

Welded bellows are constructed by welding together multiple layers or strips of metal. Each strip is precisely welded along its edges to form a bellows structure. Welded bellows provide flexibility and reliability, making them suitable for various demanding applications. However, they may have certain limitations in terms of pressure and temperature compared to forged bellows.

Both types have their separate advantages and uses based on specific application requirements. Forged bellows excel in high-pressure and high-temperature applications, while welded bellows offer flexibility and reliability in a wider range of operating conditions. The selection of the bellow type depends on factors such as the operating environment, pressure, temperature, valve size, and the specific needs of the application.

Applications of Bellow Sealed Globe Valves

Bellow sealed globe valves find application in a wide range of industries and processes where precise fluid control, reliable sealing, and enhanced safety are essential. Some key industries and applications where bellow sealed globe valves are commonly utilised include:

- Oil and Gas

Bellow sealed globe valves play a crucial role in oil and gas production, refining, and distribution processes. They are used in pipelines, offshore platforms, refineries, and petrochemical plants for controlling the flow of various fluids, including crude oil, natural gas, and refined products. - Chemical and Petrochemical

In chemical processing plants and petrochemical facilities, bellow sealed globe valves are employed to regulate the flow of corrosive and hazardous fluids, such as acids, alkalis, solvents, and volatile organic compounds. Their excellent sealing capabilities and resistance to chemical corrosion make them an ideal choice for ensuring safety and preventing leakage in these demanding environments. - Power Generation

Bellow sealed globe valves are widely used in power generation plants, including thermal power plants, nuclear power plants, and renewable energy facilities. They are utilised for controlling steam, condensation, and other fluids in various processes, such as boiler feedwater systems, steam turbine control, and cooling water systems. Bellow sealed globe valves provide reliable sealing and precise control, contributing to the efficient and safe operation of power generation facilities. - Water Treatment

Bellow sealed globe valves play a vital role in water treatment plants and wastewater treatment facilities. They are used for regulating the flow of water, chemicals, and sludge in processes such as filtration, disinfection, sedimentation, and chemical dosing. They ensure accurate control and prevent leakage to the environment, maintaining the integrity of the water treatment systems. - Pharmaceutical and Food Processing

In industries where hygiene and sanitary requirements are critical, such as pharmaceutical manufacturing and food processing, bellow sealed globe valves are employed to control the flow of fluids without the risk of contamination. These valves are designed to meet stringent hygiene standards, ensuring the integrity of the production processes and preventing cross-contamination.

These are just a few examples of the wide-ranging applications of bellow sealed globe valves. Their versatility, reliability, and sealing capabilities make them indispensable components in numerous industries where precise fluid control is crucial for operational efficiency, safety, and environmental protection.

Advantages of Bellow Sealed Globe Valves

Bellow sealed globe valves offer several distinct advantages over traditional globe valves. These advantages contribute to their widespread adoption in various industries.

Long life

Bellow sealed globe valves are designed to have a long service life. The bellows are made of high-strength materials and offer excellent resistance to corrosion, high pressures, and temperature variations. Their robust construction ensures that bellow sealed globe valves can withstand the rigours of continuous operation, reducing the need for frequent replacements and minimising downtime.

Less Maintenance

Bellow sealed globe valves offer the advantage of reduced maintenance expenses, as they do not require regular retorquing of gland sealing mechanisms. The bellows provide a reliable and long-lasting seal, ensuring consistent performance without the need for frequent adjustments or replacements. This significantly reduces maintenance costs and labour requirements, allowing for enhanced operational efficiency and cost savings over the valve’s lifespan.

Reduced Gland Leakage

One of the key benefits of bellow sealed globe valves is their ability to eliminate gland leakage. The bellows act as a barrier, ensuring a tight seal even in challenging operating conditions, thereby enhancing safety and preventing costly leaks. A bellow sealed globe valve offers ‘dual’ sealing by utilising the bellows as well as the gland packing to protect against leakage.

Emissions Control

Bellow sealed globe valves excel in environmental protection and emissions control. Their construction ensures compliance with stringent industry standards, resulting in a safer and more sustainable working environment. By effectively containing fugitive emissions, these valves contribute to a significant reduction in air pollution and promote better environmental stewardship.

Choose the Right Bellow Sealed Globe Valves

Bellow sealed globe valves provide a reliable sealing solution that minimises the risk of leaks, enhances safety, and promotes environmental sustainability. With their robust construction and resistance to corrosion, pressure, and temperature variations, these valves withstand demanding industrial environments, reducing downtime and operational costs.

If you are looking for bellow sealed globe valves or any other type of industrial valves for your specific application, get in touch with John Valves. With our expertise and commitment to excellence, we offer a comprehensive range of valves designed to meet the specific needs of various industries, ensuring durability, longevity, and reliable performance.

Our dedication to customer satisfaction and adherence to industry standards make us a reputable choice for procuring top-quality industrial valves tailored to your requirements.

To find the perfect bellow sealed globe valve or explore our range of industrial valves, contact John Valves today.