Their differences are crucial when we have to choose between a rising-stem gate valve and a non-rising-stem one for our working system. Gate valves represent a fundamental, recurrent wok in industries involving the presence of fluid. Characterised as close-off or isolation valves are more commonly used to stop fluid flow in pipelines, especially in industries such as oil and gas, water treatment plants, and others. Gate valves can be divided into two main categories, namely rising stem gate valves and non-rising stem gate valves according to the structure. Although they are both designed to provide the same primary purpose, they differ in their design, operating principle, as well as their applications

Structural and Operational Differences

Stem Movement and Visibility

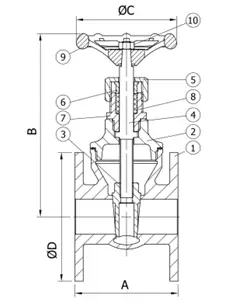

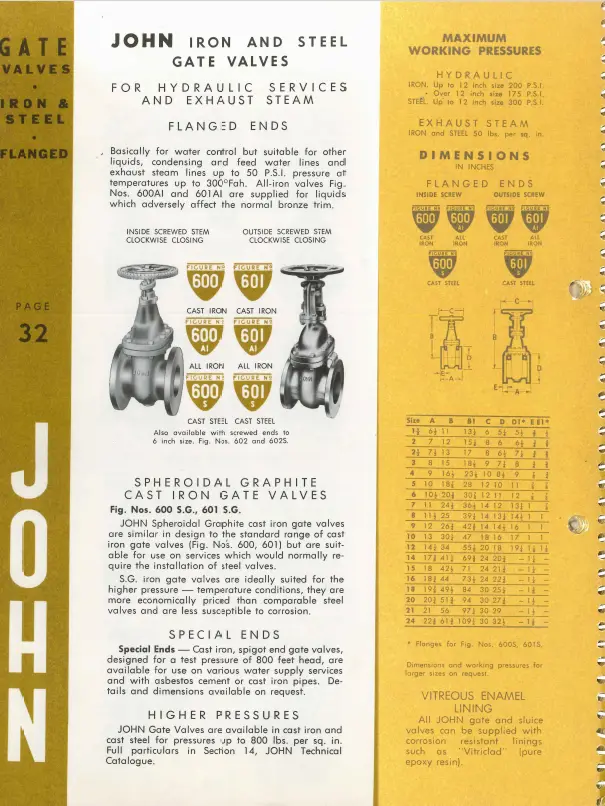

Rising stem gate valves feature a stem that visibly moves up or down as the valve is operated. When the valve is opened, the stem rises out of the valve body, providing a clear indication of the valve’s position. The rising stem connects to a stem nut on the valve bonnet or a separate bracket, and as the handwheel is turned, the stem and the gate rise together. The John Fig 600 range are available for this selection.

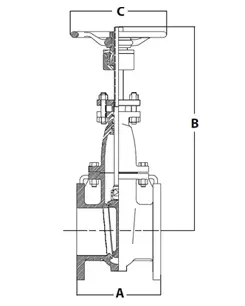

In non-rising stem gate valves, the stem does not move up or down externally. Instead, the stem remains static while only the gate inside the valve moves up or down when the handwheel is turned. The stem threads are located inside the valve body, making them less visible and giving the valve a more compact design. Because the stem does not extend outwards, non-rising stem valves do not provide visual feedback on whether the valve is open or closed, which can be a disadvantage in some applications. The John Fig 601 range are available for this selection.

Design and Space Requirements

The design of a rising stem valve requires additional vertical space to accommodate the stem as it moves upward. This means that they need more clearance, which can be a limiting factor in installations with confined space. However, this extra space provides the benefit of easier maintenance and lubrication of the stem threads. Non-rising stem gate valves have a more compact design, making them ideal for areas where vertical space is limited, such as underground installations or pipelines located in tight enclosures. Their smaller footprint also makes them easier to install in congested pipe networks. However, the compactness comes at the cost of more challenging maintenance, especially when dealing with internal stem threads exposed to process fluids.

Thread Placement and Maintenance:

In rising stem gate valves, the threads are located outside the valve body, keeping them away from the process fluid. This allows for easier access for lubrication and maintenance, resulting in smoother operation and reduced wear over time. The external threads are less prone to corrosion, which contributes to a longer valve lifespan. The threads of non-rising stem gate valves are situated inside the valve body, meaning they come into direct contact with the process fluid. This exposure can lead to thread corrosion or buildup of debris, making maintenance more complex and potentially shortening the valve’s lifespan. Moreover, lubrication of internal threads is more challenging, which can affect the valve’s smoothness of operation over time.

Visual Indication of Valve Position

The most distinct feature of rising stem gate valves is their ability to provide a clear visual indication of the valve’s position. As the stem rises, operators can easily see if the valve is fully open, partially open, or closed. This visual feedback is advantageous in large industrial plants or areas where the valve’s position needs to be frequently checked. Non-rising stem gate valves do not offer this visual cue, as the stem remains at a constant height regardless of the gate’s position. As a result, operators need to rely on additional indicators or physically verify the valve’s position. This lack of visual feedback can lead to potential errors or inefficiencies in operations where quick position identification is critical.

Suitability for Different Applications:

Rising stem gate valves are preferred in applications that demand high reliability and durability, such as in high-pressure, high-temperature environments like oil and gas pipelines or power plants. Their external threads and visual position indicator make them suitable for above-ground installations where space and maintenance access are not restricted. Non-rising stem gate valves are more suitable for underground or below-grade installations, such as municipal water lines or buried pipelines. Their compact design makes them easier to install in tight spaces, and they are typically used in low to moderate pressure applications where the process fluid’s properties do not heavily impact the valve’s internal components.

Choosing the Right Gate Valve: Key Considerations

When deciding between a rising stem and a non-rising stem gate valve, consider the following factors:

- Space Constraints – If space is limited, a non-rising stem gate valve may be the better option due to its compact size.

- Maintenance Requirements – Rising stem gate valves are easier to maintain because their external threads are accessible for lubrication and inspection.

- Operational Feedback – For applications that require frequent monitoring, rising stem valves provide a clear visual indication of the valve’s position.

- Exposure to Fluid – If the process fluid is corrosive or contains particulates, the internal threads of non-rising stem valves may be more susceptible to damage.

- Cost and Budget – If budget is a concern and the application does not demand high durability or visual feedback, non-rising stem valves are a more economical choice.

By understanding these differences, you can make a more informed decision and select the best gate valve for your system’s specific needs. For complex or critical applications, consulting with a valve specialist or engineer is recommended to ensure optimal performance and longevity.

John Valves has a long history in designing and manufacturing bot rising and non-rising gate valves. If you need help with customised solution or selecting the right valve speak to one of our valve experts.