Plug valves are part of fluid control systems are the lifeblood of countless industries, ensuring the smooth operation of processes that range from manufacturing to energy production. At the heart of these systems, plug valves like our Fig 301 or Fig 201, they silently play a vital role, offering exceptional control and reliable shut-off capabilities. Read on as we delve into the allure of plug valves, uncovering their distinct characteristics, advantages, and wide-ranging applications.

What are Plug Valves?

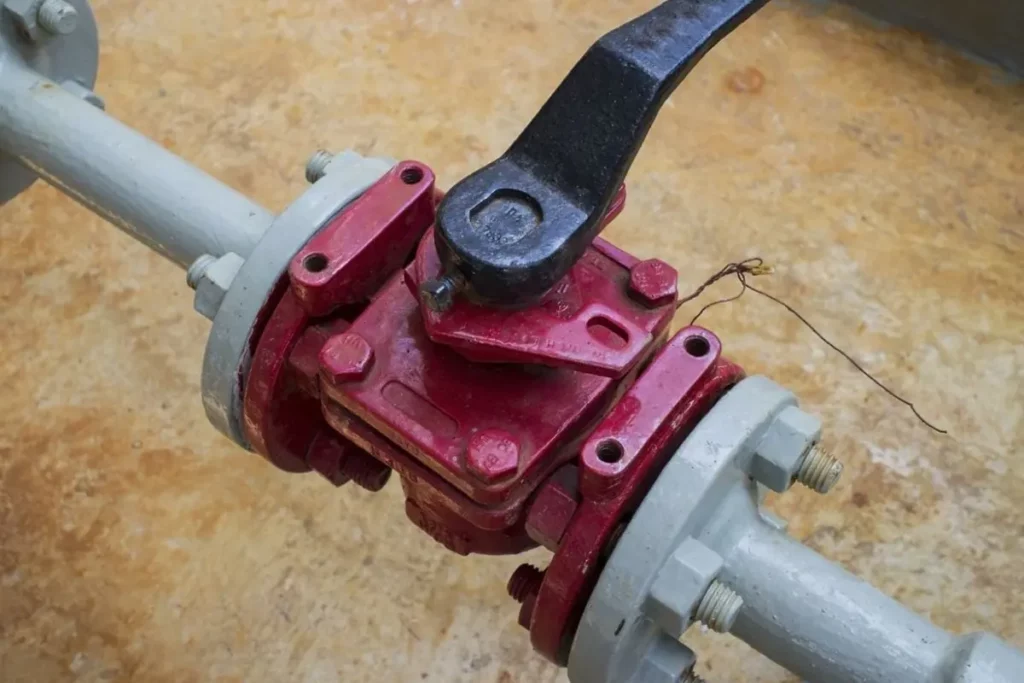

Plug valves are mechanical devices that control the flow of liquids and gases in pipelines and systems. They belong to the family of quarter-turn valves, which means they can be fully opened or closed with a 90-degree rotation of the valve handle or actuator.

The distinguishing feature of plug valves is the cylindrical or tapered plug that rotates within the valve body to obstruct or permit the flow. The plug itself has a hole or passage through its centre, allowing the fluid to pass through when aligned with the inlet and outlet ports of the valve. By rotating the plug, the passage can be partially or completely obstructed, controlling the flow rate or stopping it entirely.

Plug valves offer a simple yet effective design that allows for quick and reliable operation. They typically have a round or cylindrical body with a port on each end, providing an inlet and an outlet for the fluid. The plug fits snugly within the body and can be rotated to control the flow.

To ensure a secure seal when the valve is closed, plug valves often employ elastomeric or metal seals on the plug and valve body interface. This sealing mechanism prevents leakage and provides a tight shut-off when the valve is in the closed position.

Types of Plug Valves

Plug valves come in various types and configurations to suit different applications and operating conditions. Some common types include:

1. Lubricated Plug Valve

The lubricated plug valve is a widely used type known for its reliable sealing capabilities. It features a tapered or cylindrical plug coated with a lubricant, usually a grease or sealant, that helps reduce friction and ensures smooth operation. The lubrication forms a barrier between the plug and the valve body, minimising wear and providing a tight seal even under high-pressure conditions. Lubricated plug valves are commonly found in industries such as oil and gas, petrochemicals, and wastewater treatment.

2. Non-Lubricated Plug Valve

In contrast to lubricated plug valves, non-lubricated plug valves are designed to operate without the need for external lubrication. Instead, they utilise advanced materials and self-lubricating mechanisms to reduce friction and enhance sealing. This type of plug valve is ideal for applications where the presence of lubricants could contaminate the fluid or cause undesirable reactions. Non-lubricated plug valves are commonly used in industries such as food and beverage, pharmaceuticals, and clean energy.

3. Eccentric Plug Valve

Eccentric plug valves feature a unique design where the plug is offset from the centreline of the valve body. This eccentricity allows the plug to be completely disengaged from the flow path when in the open position, minimising wear and reducing the torque required for operation. Eccentric plug valves provide excellent throttling capabilities and are suitable for applications that require precise flow control, such as chemical processing, power generation, and water distribution systems.

4. Expanding Plug Valve

Expanding plug valves are designed to provide a tight shut-off by utilising a plug that expands radially when rotated into the closed position. This expansion creates a reliable sealing surface against the valve body, effectively preventing leakage. Expanding plug valves are commonly used in high-pressure and high-temperature applications, such as steam systems, where a secure and leak-free shut-off is critical.

Each of the above plug valve types offers distinct advantages and is chosen based on factors such as the nature of the fluid, operating conditions, and required flow control characteristics. Selecting the appropriate plug valve – you can ensure optimal performance, efficiency, and safety in your fluid handling system.

Applications of Plug valves

Plug valves, with their exceptional design and functionality, find diverse applications across multiple industries. These versatile valves play a crucial role in regulating the flow of liquids and gases in various systems, ensuring efficiency, safety, and precise control. Let’s explore some of the key applications where plug valves demonstrate their remarkable capabilities.

1. Asphalt and bitumen industries

Plug valves are a popular choice in the asphalt and bitumen industries due to their robust design and ability to handle the challenging conditions involved. Plug valves provide excellent sealing, preventing leaks of the highly viscous and often hot materials. They can be can be operated quickly and easily, even with gloves on, which is important in harsh industrial environments. Available in various port configurations (2-way, 3-way, etc.), they can handle a wide range of applications.

2. Oil piping systems

Plug valves are extensively used in oil piping systems, where they play a crucial role in regulating the flow of crude oil, refined products, and various petroleum derivatives. These valves are well-suited for handling the high pressures and demanding conditions commonly encountered in oil pipelines. Their ability to provide a tight shut-off and withstand abrasive particles makes them ideal for controlling the flow of oil and ensuring the efficient operation of oil transportation networks.

3. High-pressure & extreme temperature flow systems

Plug valves excel in high-pressure and extreme temperature flow systems, such as those found in power plants, refineries, and industrial processes. These valves are designed to handle the challenging conditions often associated with such applications. With their robust construction and reliable sealing mechanisms, plug valves can effectively manage the flow of fluids under elevated pressures and temperature extremes, ensuring safe and efficient operation in demanding environments.

4. Chemical servicing

In chemical processing industries, plug valves are widely employed to control the flow of various chemicals, acids, and corrosive substances. The materials used in plug valves can be selected to resist chemical attacks and provide excellent corrosion resistance. Their ability to handle aggressive media and provide a tight seal makes them invaluable in chemical servicing applications, protecting equipment and ensuring precise control over the flow of chemicals in diverse processes.

5. Corrosive substances processing

Whether in the pharmaceutical, petrochemical, or water treatment industries, plug valves can effectively manage corrosive fluids while maintaining a reliable seal. Their resistance to corrosion and ability to withstand aggressive environments make them a preferred choice for applications where corrosion is a significant concern, safeguarding the integrity of the system and ensuring the efficient processing of corrosive substances.

Benefits of Using Plug Valves

Plug valves have many benefits that make fluid control systems work smoothly and reliably. These benefits include.

- Another advantage of plug valves is their excellent sealing. They shut off completely when closed, minimising leakage and the flow of fluids that could be dangerous or contaminate the surroundings.

- Because you can open or close a plug valve simply by rotating it a quarter turn, they are also easy to operate. That means you can open and close one rapidly, which is useful in situations where you need to respond quickly.

- In its simplest form, a plug valve does not create either a 90-degree or a 180-degree bend, meaning that it allows fluid to pass through with little loss of pressure across the valve. This makes plug valves useful for high-flow applications – systems that operate at high pressure to push a large amount of fluid through a pipe – where system efficiency and energy savings are important.

- Plug valves can handle a wide range of media, including liquids, gases, and corrosive substances, and they are, therefore, well suited for many different types of installations, processes and applications.

- Plug valves are manufactured from resilient metals or high-performance polymers that are engineered to last. This helps to prevent wear and tear, and can withstand extremely demanding operating conditions, ensuring a longer service life.

- Bi-directional flow is a benefit of using plug valves, which means that fluid can flow either way through in the system. In addition to providing this benefit, plug valves also make installation easier because, since flow can happen in both directions, there’s no need to consider specifically which direction the fluid should move through the valve at the time of installation. Instead, all that is needed is a straightforward decision about whether it will be necessary for flow to be stopped in the direction where the plug is to be closed. This advantage is sometimes combined with the ability to switch the direction of flow by using plug valves that have more than two ports. These are called multi-way plug valves.

- Because they are made of rugged cast-iron material, have a simple design, and the plug can be pulled out easily, the valves need a few moving parts for their operation, which results in negligible maintenance and hence minimum downtime. Consequently, these valves are quite an economical option for industries.

- Plug valves are specifically built to withstand high pressure and high temperature applications with ease. They are designed to operate seamlessly under challenging conditions and maintain their integrity.

John Valves – Your Trusted Plug Valves Manufacturer in Australia

Partner with John Valves for unparalleled valve solutions and unlock the true potential of your fluid control systems. Let’s connect.